How to maintain our products?

Introduction :

Since 1956, our road marking sprayers have been used all over the world. The are recognized for their manufacturing quality, marking performance and durability. They are designed and manufactured to withstand wear and tear. Whether in terms of their operation, manufacture, or the materials used, we guarantee high-quality products.

However, to keep your product performing at its best, we strongly recommend that you maintain your sprayers regularly.

First, we will explain how our sprayers work. In general, the operation is almost the same for all sprayers, whether for paint or glass beads.

Next, we will give you some useful tips on how to properly maintain your sprayers.

Main text :

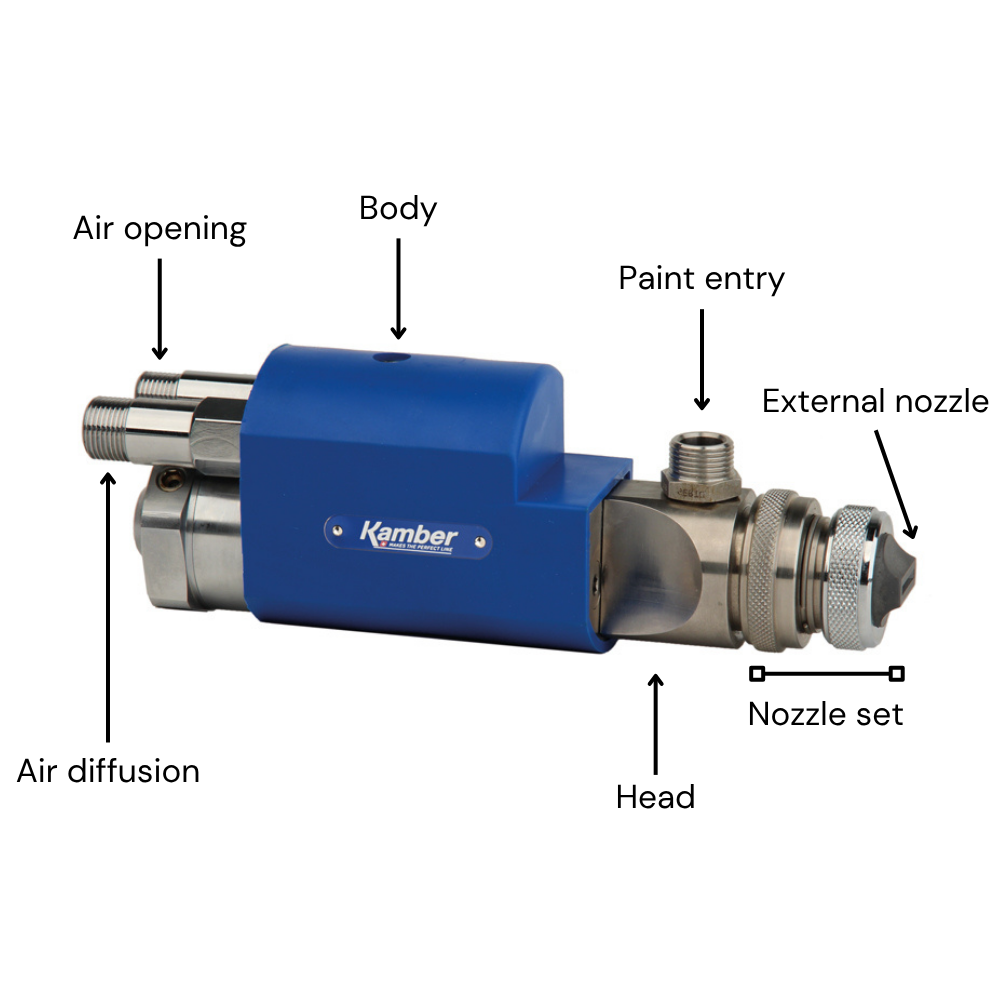

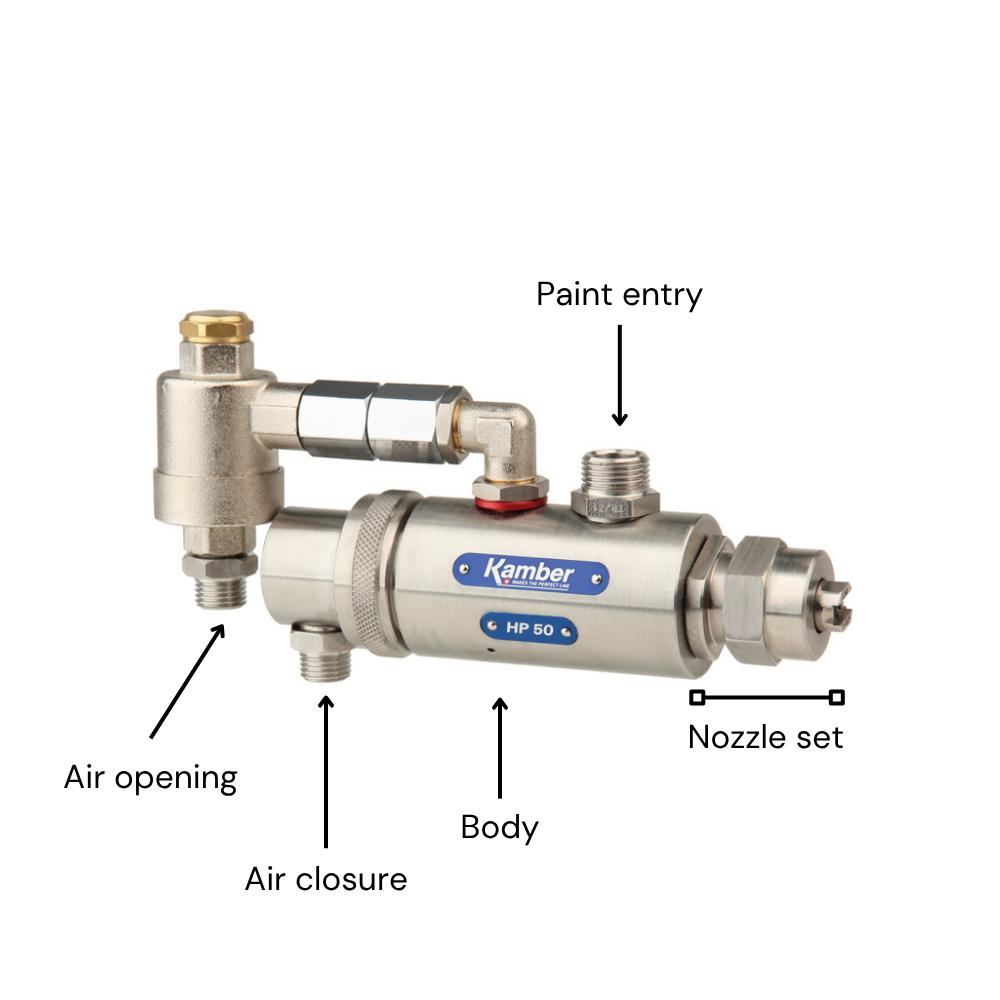

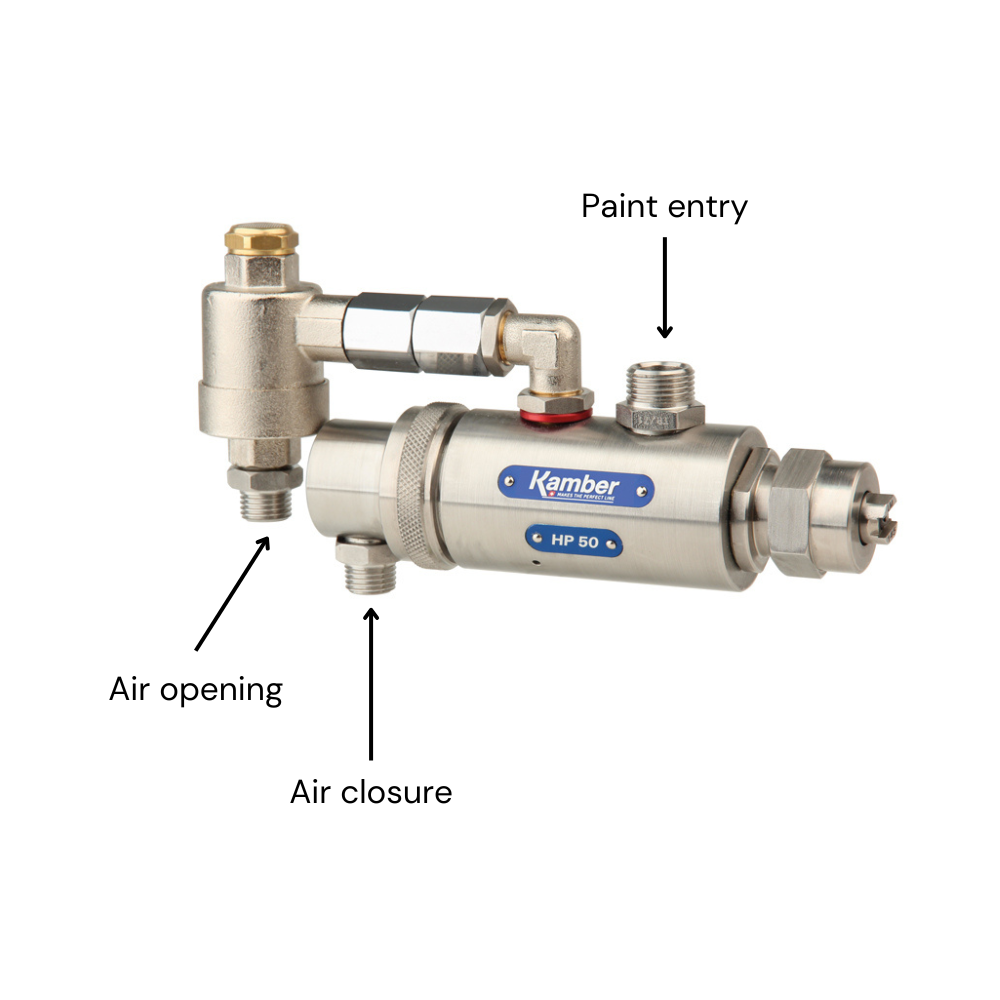

Structure of our low- and high-pressure paint sprayers

All our paint sprayers generally consist of a body and a head, two distinct parts that are connected to each other (except for models 84 and HP50). At the end of our sprayers or heads, there is a nozzle or set of nozzles that allows the paint to be sprayed in a triangular pattern. Our sprayers are also equipped with an inlet for paint (two inlets for high-pressure sprayers), an inlet for rinsing (low-pressure sprayers), and air inlets to activate the sprayers (opening and closing on certain models) and to diffuse the paint.

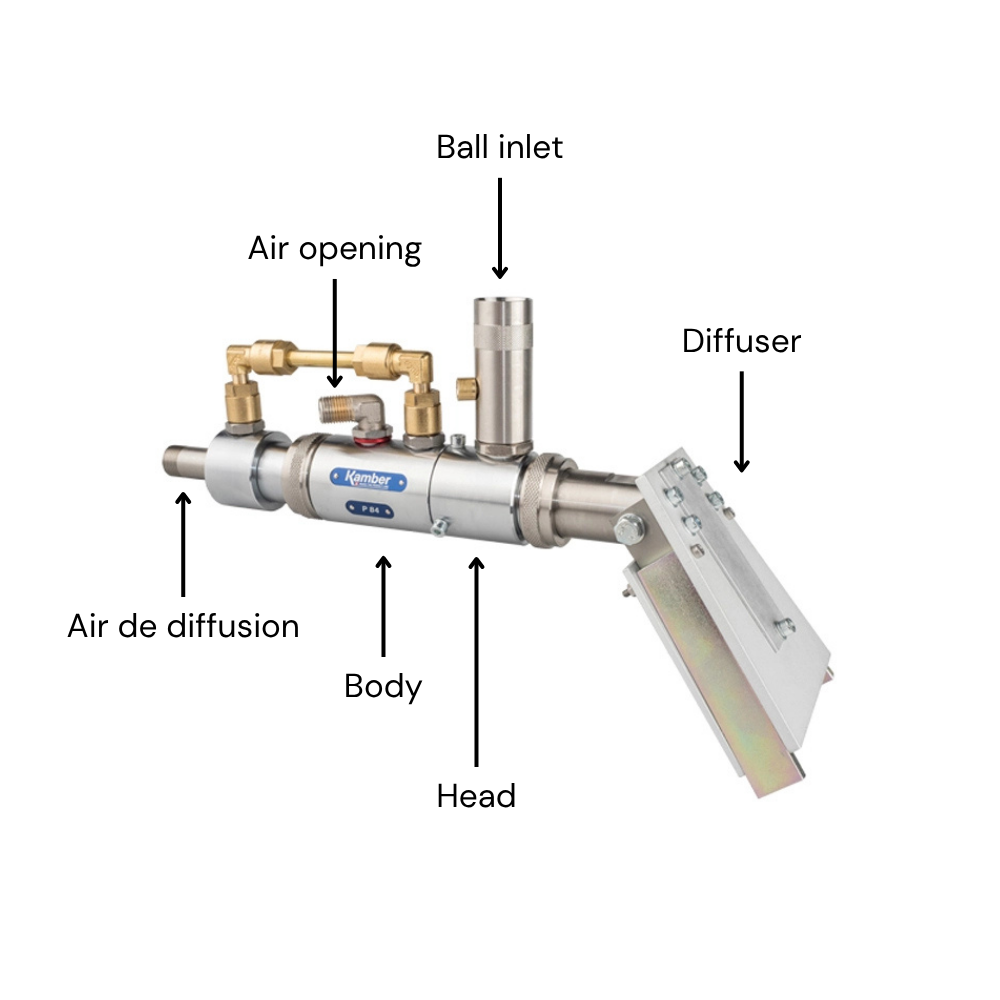

Structure of our glass bead sprayers

Our glass bead sprayers have virtually the same composition, with a body, a head, and a nozzle at the outlet that allows the glass beads to be sprayed. The only difference is the presence of a diffuser at the outlet, which allows the spread of the beads to be controlled and the angle of the glass beads relative to the road to be varied. Our sprayers are also equipped with an inlet for glass beads at the head and air inlets to activate the sprayer (opening and closing on the P90 model) as well as to diffuse the glass beads (except on the P86).

How does it works

Paint sprayers

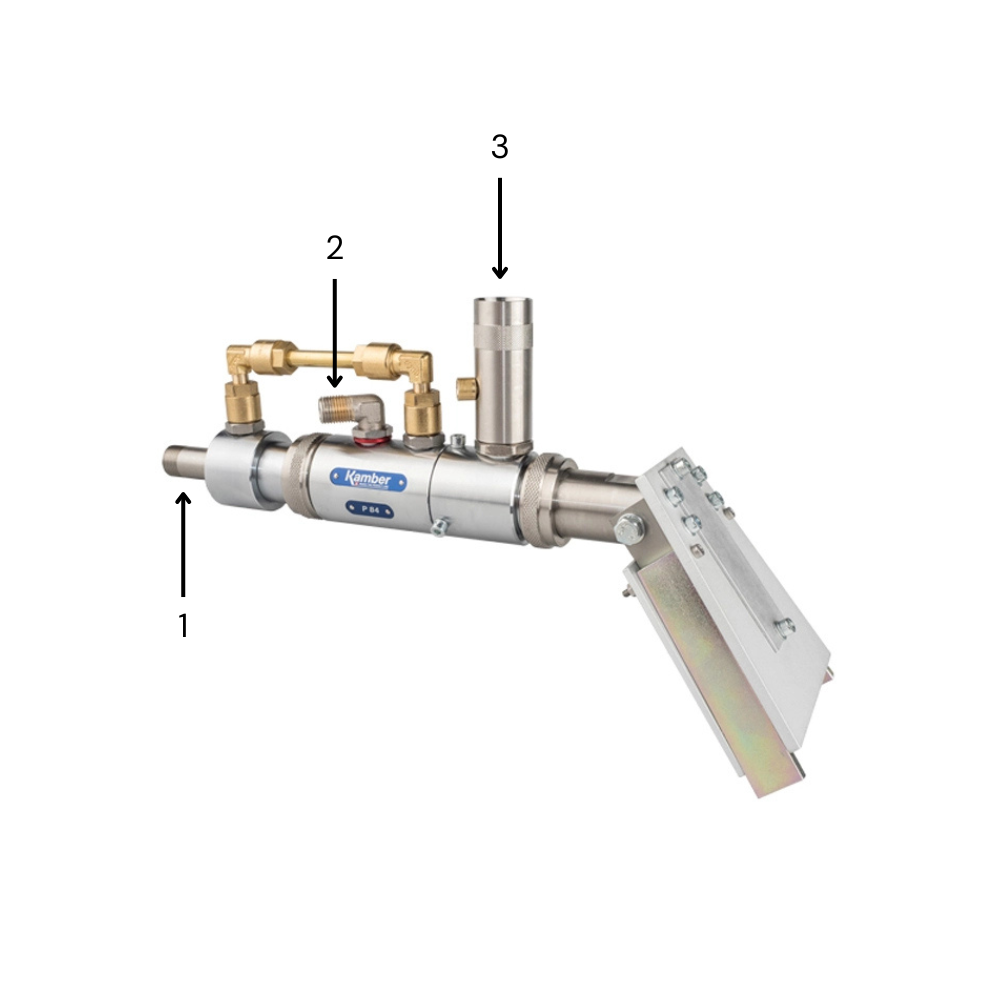

Our low-pressure paint sprayers work as follows. The paint, coming from the machine’s pressurized tank, enters the sprayer head see 2. At the same time, to start marking, the sprayer opens by injecting air see 3 (opening pressure between 6 and 8 bar). At the same time, diffusion air is injected into 1 to spray the paint. This diffusion air, which passes through the body of the sprayer, arrives in an air nozzle at the head of the sprayer and is thus able to spray the paint, which passes through an external nozzle to produce a triangular spray pattern.

Our high-pressure sprayers work differently because there is no diffusion air. The paint, coming from the tank via a high-pressure pump, enters the sprayers head at a pressure between 80 and 200 bar. At the same time, to start marking, the sprayers open by injecting air (opening pressure approx. 6 bar). The high-pressure paint will pass through an external nozzle with a small diameter orifice (between 0.4 and 2.5 mm), which allows it to be automatically sprayed to produce a triangular spray pattern

Glass bead sprayers

The operation of our glass bead sprayers is relatively similar to that of our paint sprayers.

The glass beads, coming from the machine’s tank (pressurized or non-pressurized), enter the sprayer head at 3. At the same time, to start marking, the sprayer opens by injecting air at 2 (opening pressure approximately 6 bar). At the same time, diffusion air is injected into 1 to push and accelerate the glass beads. This diffusion air, which passes through the body of the sprayer, arrives in an air nozzle at the closing piston. The glass beads then pass through a calibrated nozzle to be projected into the diffuser and obtain the spray of beads for marking. In the case of a machine with a non-pressurized tank, the glass beads flow by gravity into the sprayer head.

Maintenance of a sprayer

Regular maintenance of road marking sprayers is essential to prevent breakdowns, extend their service life, and ensure high-quality marking.

For paint sprayers, one of the crucial points is to prevent paint from drying inside the sprayer and in the nozzles, which could lead to blockages that are difficult to clean and cause the sprayer to malfunction. It is essential never to shut off the air supply before the paint supply, as this could cause the paint to flow back into the sprayer’s air ducts. Similarly, always ensure that the products used are compatible; never rinse a sprayer that has been used with solvent-based paint with water, and vice versa, as this could cause a chemical reaction or irreversible deposits.

Daily maintenance is the best way to keep your equipment in good working order. For paint sprayers, this includes systematic rinsing after use, cleaning with compressed air or a suitable rinsing liquid (never immerse the sprayer in a tank of rinsing product, as this may damage the internal seals). Our low-pressure paint spray guns are equipped with a side hole, to which a connector can be added on request; this allows the introduction of cleaning fluid.

During a prolonged shutdown of the machine or at the end of the working day, to preserve the external nozzle, it is advisable to dismantle it and then soak it in the appropriate rinsing liquid for the paint used. In the event of prolonged downtime (1 month or more), it is recommended that the components of the sprayer’s paint circuit be disassembled, followed by soaking the metal parts in the appropriate rinsing fluid for the paint used. If the machine is stopped for a long time, paint residues inside the sprayer can dry out and cause the sprayer to clog.

Glass bead sprayers, often used with specific paints, are subject to faster mechanical wear due to abrasion caused by the friction of the glass beads. This requires frequent replacement of certain wear parts, but there is no risk of internal blockages due to paint residue.

To facilitate maintenance, Kamber provides special tools for disassembly as well as suitable, original Kamber spare parts, which are sent directly to companies. Assembly forms are also available on request, although these are limited to certain models. Finally, it is worth remembering that proper maintenance not only improves the reliability of the sprayers, but also contributes to the profitability of construction sites (no breakdowns means fewer stoppages) and safety on construction sites (fewer stoppages means shorter intervention times and a reduced risk of accidents).

Conclusion :

Thanks to their robustness and precision, our road marking sprayers have been used by professionals around the world for nearly 70 years. But like any high-performance tool, their effectiveness depends largely on how well you maintain them. Understanding how they work, adopting the right maintenance practices, and using the right products are essential for ensuring optimal longevity. By following our advice and taking advantage of the original tools and parts we provide, you can ensure that your equipment performs consistently and reliably.

Regularly maintaining your sprayers not only protects your investment, but also maintains a high level of quality in all your markings.